Heat exchanger cleaning of a joint unit of PetroChina Petrochemical Company

Release time:2017-05-27Author:Click:3019

1、Cleaning range

Process number | Device name | Model | Cleaning target | Parra Stern | |

Ex heat exchanger | E-1001 | A regular heat exchanger for crude oil | BES800-4.0-160-6/25-4I | Heavy oil, iron sulfide | D740 742 |

E-1003 | An ordinary three - line (three) heat exchanger for crude oil | BES1000-4.0-265-6/25-4Ib | Heavy oil, iron sulfide | D740 742 | |

E-1004/1、2 | Crude oil one in one heat exchanger | BES1100-2.5-335-6.0/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1005/1、2 | Crude oil one line heat exchanger | BES900-4.0-215-6/25-2Ib | Heavy oil, iron sulfide | D740 742 | |

E-1201/1-4 | Crude oil reduction and reduction cycle heat exchanger | BES1200-4.0-400-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1202 | Crude oil is reduced by two (3) heat exchanger | BES1200-1.8/2.2-400-6.0/25-2Ib | Heavy oil, iron sulfide | D740 742 | |

E-1203/1、2 | Crude oil reduced slag (four) heat exchanger | BES1200-2.5-400-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1203/3 | Crude oil reduced slag (four) heat exchanger | BES1200-2.5-505-6.0/19-2 Ib | Heavy oil, iron sulfide | D740 742 | |

Off heat exchanger | E-1006/1、2 | After removal of crude oil, a constant weight (two) heat exchanger | BES1200-2.5-400-6.0/25-2Ib | Heavy oil, iron sulfide | D740 742 |

E-1007 | An ordinary three - line (two) heat exchanger for crude oil | BES800-2.5-160-6.0/25-4I | Heavy oil, iron sulfide | D740 742 | |

E-1008/1、2 | Crude oil heat exchanger | BES1100-2.5-335-6.0/25-2Ib | Heavy oil, iron sulfide | D740 742 | |

E-1009 | After removal of crude oil, an ordinary three wire (a) heat exchanger | BES800-4.0-165-6/25-2Ib | 重油、硫化亞鐵 | D740 742 | |

E-1010/1、2 | After removal of crude oil, a constant weight (1) heat exchanger | BES1200-4.0-400-6.0/25-2Ib | Heavy oil, iron sulfide | D740 742 | |

E-1204/1、2 | The crude oil is reduced by three (three) heat exchanger | BES1100-2.5-325-6/2-2I | Heavy oil, iron sulfide | D740 742 | |

E-1218/1、2 | Crude oil heat exchanger | BES1200-2.5-505-6/19-2I | Heavy oil, iron sulfide | D740 742 | |

E-1205/1、2 | After removing crude oil, a slag reduction (3) heat exchanger is used | BES1100-2.5-325-6/25-4I | Heavy oil, iron sulfide | D740 742 | |

E-1206/1、2 | The crude oil is reduced by two (two) heat exchanger | BES1100-4.0-335-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1208/1、2 | The crude oil is reduced by three (two) heat exchanger | BES1100-4.0-335-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1219/3、4 | After removal, crude oil is reduced by 1 (1) heat exchanger | BES1100-4.0-335-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1219/1 | After removal, crude oil is reduced by 1 (1) heat exchanger | LBQ1200-2.5-LT2 | Heavy oil, iron sulfide | D740 742 | |

Flash heat exchanger | E-1209/1、2 | One off two and one medium heat exchanger | BES1100-4.0-325-6/25-4I | Heavy oil, iron sulfide | D740 742 |

E-1210/1-4 | Flash bottom slag reduction (I) heat exchanger | BES1200-2.08-400-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1210/5 | Flash bottom slag reduction (I) heat exchanger | BES1200-4.0-400-6.0/25-2 Ib | Heavy oil, iron sulfide | D740 742 | |

E-1211/1-4 | Flash bottom slag reduction (two) heat exchanger | BES1100-4.0-335-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1212/1-4 | Flash bottom minus three (a) heat exchanger | BES1100-4.0-335-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1213/1-4 | Flash bottom minus 2 (two) heat exchanger | BES1100-4.0-335-6/25-2I | Heavy oil, iron sulfide | D740 742 | |

E-1214/1、2 | Flash bottom minus 2 (1) heat exchanger | BES1200-4.0-500-6/19-2I | Heavy oil, iron sulfide | D740 742 | |

E-1214/3一5 | Flash bottom minus 2 (1) heat exchanger | BES1200-4.0-500-6/19-2Ib | Heavy oil, iron sulfide | D740 742 | |

Constant weight | E-1023/1、2 | Often restart the shutdown cooler | BES1200-4.0-400-6.0/25-2Ib | Heavy oil, iron sulfide | D740 742 |

Vacuum residue | E-1217/1-3 | Slag less water cooler | BES1200-2.5-400-6/25-2I | Heavy oil, iron sulfide | D740 742 |

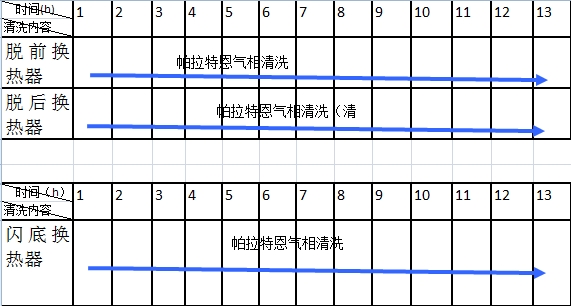

2、time node:

3、Cleaning effect

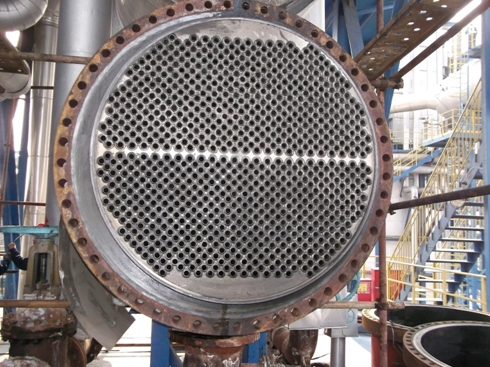

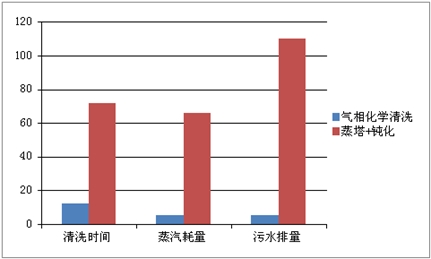

1) The gas phase cleaning of parattah en atmospheric column, vacuum tower, distillation tower of hydrogen sulfide (H2S), iron sulfide (FeS), light oil cleaning, after cleaning device inside the hydrogen sulfide and other toxic gases content is 0, visual observation device internal clean and can see no light oil residue device for inner wall of metal color.

2)The end of the cleaning device opens the manhole, the operator carries the instrument to detect, and the hydrogen sulfide alarm does not alarm.

3) After opening the manhole, after six hours of ventilation, the maintenance personnel can enter the equipment and start the operation directly.

After testing, the PetroChina Dagang Petrochemical Company shutdown maintenance device, by Parra Stern (Paratene) after gas phase cleaning to achieve the desired objectives, improve production efficiency and get the recognition and affirmation of the manufacturers.

- Previous article:No

- Next article:No